Before becoming Konica Minolta’s account manager for education, Tony Robertson was a head of department at a leading public school in Queensland.

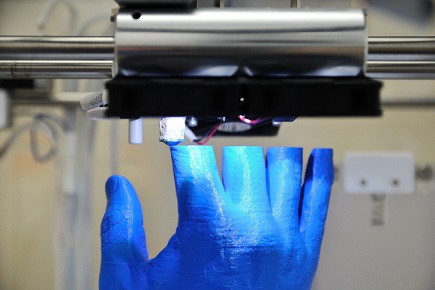

At that time, the school staff and students were experiencing some issues with their desktop 3D printers, which were filament-based.

Robinson, who had a link with the Queensland University of Technology, approached an academic who had been researching this technology to ask about her background and what she’d learned from the studies she’d been involved with.

The academic, who had travelled across the US and Europe, mentioned that Konica Minolta’s 3D systems and printers were particularly effective, which prompted Robinson to see for himself. A short time later, he purchased the first 3D printer for his school.

Giving time back to teachers

Robinson told The Educator that as a head of department, he wanted to ensure that he avoided the issue of teachers spending so much time setting up 3D printers for students.

“The kids are really keen and eager to get their 3D print jobs back, but we were finding that they were losing a bit of enthusiasm because of the time it took for the teachers to actually get that one print at a time off and give it back to the students,” he said.

“So there can be issues around reliability, time and also the service. I actually had to send two of those filament style printers to Melbourne to get fixed, and then had to bring them back and they actually didn’t work after the first time.”

When the Konica Minolta 3D printers arrived, Robinson said he found them to be very reliable.

“We had no failed print whatsoever, and the school has had it for over a year and a half now,” he said.

“So we can actually do a whole class set in one build, and that can all be done overnight. The next morning all that class can actually have their 3D print back to them.”

Robinson pointed out that if there are any issues, same day local support is on hand to resolve them.

Preparing students for the future

To Robinson, 3D printing is not only about reliability, time and service but preparing children with critical 21st century skills that are in demand, and likely to be required in many emerging industries, such as medical science, defence and engineering.

“We’ve really got to demonstrate those thinking skills and get kids to think critically and creatively around the designs or engineering projects,” he said.

“If they can actually learn those lifelong lessons, I think they’ll go really well towards getting a career somewhere.”

Robinson says there are some things for principals to keep in mind when navigating some of the common pitfalls of 3D printing.

“Principals need to adopt a whole school approach rather than in just one faculty,” he said.

“This means that principals need to look at how 3D printing can be used across the whole school, and probably have a central area where the kids can actually get to that fairly easily rather than just locked away in one faculty area.”

One of the greatest benefits of 3D printing, says Robinson, is that it can be utilised across almost any subject area.

“It’s up to the teachers as to how they do that, but with engineering, the design syllabus, prototyping, designing and critical analysis are key learning areas for students to utilise 3D printing,” he said.

“There’s also a push from the STEM side of it from certain sectors in the education system, so you really want to bring that theory and that understanding to a tangible and hands on reality for students. They can get this through 3D printing.”